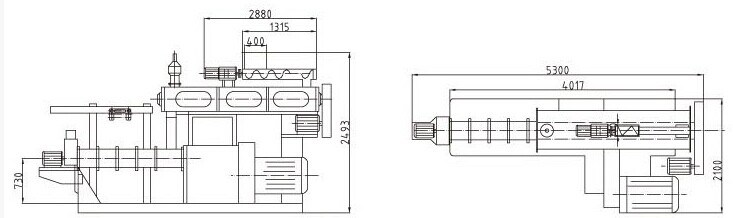

DP118 Twin screw extruder machine for pet food and fish feed

1. The machine is equipped with

PLC automatic control

2. Under the advanced touch

operation, the order can be fulfilled with your touch.

3. With the feeder of frequency

and speed control, the uniform feeding can be achieved.

4. The gearbox of the main

engine is equipped with gear oil pump cooling system, lubricating system, twin

screw extruding and pumping mechanism and dual-shaft extension differential

modulator,

5. which can cure the materials

completely and make the gelatinization degree more than 98%.

6. With a great variety of raw

materials, grease contained can be over 12% in the food formulation.

7. The screws possess the function

of self-cleaning. When restarting the machine or changing materials, you do not

need to clean bores and screws.

8. The main engine can be

adapted to different raw materials by frequency control and the discharging

chopper is controlled by frequency conversion so as to adjust the length of

materials.

9. Made of special materials by

special process, the screws and shells are tolerant to wear and pressure.

10. The feedstuff is sterilized

by high temperature and pressure in the course of processing so that we can

guarantee the foodstuff is clean and safe.

11. The bore diameter (d) of the

cylindrical discharging die is 0.8mm to 10mm.

12. We can also customize die

bores of other special shapes according to requirements of customers.

13. The machine can be applied

to process puffed feedstuff (floating or sinking), the stability of which can

last for more than 24 hours in water.

In addition, this machine can be applied to

process the bait for aquarium fish, pets` food, porket feed, puffed feed for

young animals, livestock and poultry as well as other puffed food of high

quality.

Main Technical Parameter:

|

Model |

DP-118 |

|

Capacity |

1.0~2 Tons per hour |

|

Main Motor Power |

110kw |

|

Conditioner Power |

5.5kw |

|

Cutting power |

4kw |

|

Feeder Power |

0.75kw |

|

Pellet feed size |

0.8~10mm |

|

Form rate |

≥98% |

|

Water content of the product |

≤10% |

|

Installed capability |

300kw |

|

Steam consumption |

300kg/h |